What You Need to Know About 3D Scanning for Projects

Wiki Article

Enhancing Manufacturing Processes: The Effect of 3D Laser Scanning on Quality Control

3D laser scanning modern technology is changing quality assurance in manufacturing. By giving specific measurements and high-resolution information, it enables producers to recognize inconsistencies from requirements effortlessly. This improvement not just improves examination processes yet also enhances functional efficiency. 3D Scanning. The execution of this modern technology comes with its very own set of difficulties. Checking out these facets exposes the more comprehensive effects for markets and the future landscape of manufacturing

Understanding 3D Laser Scanning Modern Technology

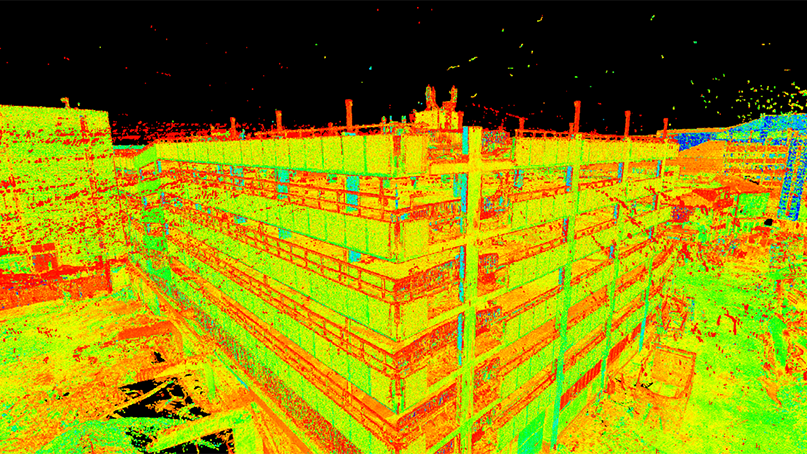

3D laser scanning modern technology has evolved considerably in current years, its essential principle continues to be straightforward: catching the specific geometry of objects making use of laser light beams. This innovation employs laser light to gauge ranges in between the scanner and various factors on a things's surface area. The data gathered is then processed to create an in-depth 3D design, precisely showing the measurements and shapes of the checked item.Normally, 3D laser scanners can be categorized into two primary types: call and non-contact scanners. Get in touch with scanners physically touch the challenge collect dimensions, whereas non-contact scanners make use of laser light beams to capture information from a distance. The convenience of this modern technology enables its application across different markets, consisting of design, manufacturing, and building. Its capability to produce high-resolution versions helps with quality control, reverse design, and fast prototyping, eventually boosting style accuracy and efficiency in manufacturing processes.

Advantages of 3D Laser Scanning in Manufacturing

As manufacturers look for to boost effectiveness and precision in their procedures, the benefits of 3D laser scanning have become progressively obvious. This cutting-edge modern technology enables quick and extremely exact measurements of complex geometries, substantially lowering the moment required for quality checks. By capturing comprehensive information, suppliers can identify disparities early in the production procedure, thus lessening waste and revamp costs.3D laser scanning helps with better style validation, allowing engineers to contrast as-built conditions with original specs. This capability assures that any inconsistencies are without delay resolved, enhancing general product top quality. In addition, the modern technology sustains the development of electronic doubles, which can be utilized for simulations and process optimizations. Consequently, makers not just enhance their functional performance however likewise enhance their affordable advantage on the market. Generally, the combination of 3D laser scanning represents a transformative step towards attaining higher criteria in manufacturing quality assurance.

Assimilation of 3D Laser Scanning Into High Quality Control

Integrating 3D laser scanning into quality control procedures boosts the accuracy and performance of examinations throughout manufacturing. This technology allows makers to catch in-depth, high-resolution data of assemblies and parts, permitting exact dimensions and contrasts versus style requirements. By employing 3D laser scanning, organizations can determine inconsistencies from tolerances better, which is crucial for preserving item integrity.

Real-World Applications and Study

Real-world applications of 3D laser scanning in making demonstrate its transformative impact throughout various industries. Aerospace firms use this technology to perform exact inspections of parts, ensuring they fulfill rigid safety requirements. A remarkable instance involved a leading airplane maker that employed 3D laser scanning to enhance its top quality control procedures, significantly lowering assessment times and mistakes.In the automobile sector, makers have applied laser scanning to create electronic twins of their vehicles, enabling real-time modifications throughout manufacturing. One auto firm reported a 30% reduction in rework expenses after integrating this modern technology right into their production line.

In the customer products market, business are utilizing 3D laser scanning for quick prototyping, enabling for quicker iterations and boosted item designs. These applications illustrate how 3D laser scanning not only boosts accuracy however additionally enhances performance and innovation throughout numerous manufacturing domain names.

Overcoming Difficulties in Implementation

Applying 3D laser scanning in producing presents several difficulties that organizations need to navigate to totally understand its advantages. One considerable hurdle is the preliminary price of equipment and software application, which can discourage companies from embracing this modern technology. Furthermore, incorporating have a peek at this site 3D laser scanning right into existing workflows calls for conquering resistance to change amongst staff members, necessitating complete training programs to guarantee proficiency. Data monitoring likewise poses an obstacle, as the high volume of details produced by 3D scanning should be properly refined and assessed to obtain actionable understandings. Additionally, compatibility concerns with legacy systems may hinder smooth integration, demanding potential upgrades or modifications. Dealing with these difficulties is crucial for producers intending to enhance quality assurance and optimize manufacturing procedures. By creating clear approaches for training, financial investment, and data monitoring, firms can minimize these challenges and release the transformative potential of 3D laser scanning in their procedures.Future Patterns in 3D Laser Scanning for Manufacturing

As manufacturing continues to progress, the combination of 3D laser scanning with increased automation is anticipated to transform manufacturing processes. Boosted data analytics will play a vital role in boosting and optimizing process quality assurance. These patterns highlight the capacity for higher performance and precision in making settings.

Enhanced Automation Assimilation

Although the combination of automation in production has actually been gradual, the future of 3D laser scanning is poised to increase this fad considerably. As producing processes end up being significantly complex, the need for accurate, real-time measurements expands. 3D laser scanning modern technology uses automated information capture, reducing labor prices and lessening human mistake. This assimilation allows manufacturers to enhance quality assurance procedures, enabling rapid detection of discrepancies in manufacturing. Additionally, the alignment of 3D laser scanning with robotics and automated systems promotes smooth operations, enhancing overall efficiency. As producers adopt these innovative innovations, they can anticipate better precision and efficiency, placing themselves competitively in a quickly progressing market. The harmony in between automation and 3D laser scanning notes a substantial leap forward in producing development.Boosted Information Analytics

The integration of automation has actually led the way for developments in information analytics within the domain name of 3D laser scanning. Makers are progressively leveraging innovative algorithms and artificial intelligence methods to examine large datasets produced by laser scans. This boosted data analytics capacity permits real-time tracking of manufacturing processes, enabling the identification of inconsistencies and defects extra efficiently than typical approaches. Anticipating analytics can foresee possible issues, considerably minimizing downtime and enhancing general performance. The ability to visualize information in three measurements supplies deeper insights right into production operations, promoting much better decision-making. As 3D laser scanning modern technology remains to develop, the role of data analytics will become significantly essential in driving technology and preserving competitive advantage in production.Frequently Asked Inquiries

What Industries Advantage the Many From 3D Laser Scanning?

The industries that benefit most from 3D laser scanning consist of manufacturing, building, aerospace, automotive, and health care. These industries use the innovation for precision measurements, high quality assurance, and effective layout procedures, considerably boosting general functional effectiveness.How Does 3D Laser Scanning Compare to Standard Dimension Approaches?

3D this content laser scanning supplies greater precision and speed compared to standard dimension approaches. It records comprehensive geometries quickly, minimizing human mistake and assisting in better analysis, which eventually boosts overall top quality control in numerous sectors.What Is the Cost of Implementing 3D Laser Scanning Technology?

The cost of implementing 3D laser scanning modern technology differs significantly, typically ranging from $10,000 to $100,000, depending on software application, training, and tools. Organizations must evaluate these expenditures versus potential performance and top quality improvements.Exist Specific Software Application Needs for 3D Laser Scanning?

Yes, 3D laser scanning needs details software application, including data handling and modeling applications. Typical choices incorporate CAD software application, point cloud processing devices, and specialized applications that help with the combination and analysis of checked data for perfect results.Exactly how Long Does a Typical 3D Laser Scanning Refine Take?

A normal 3D laser scanning procedure can take anywhere from a few minutes to a number of hours, depending on aspects like the size of the things, complexity of the setting, and called for degree of detail for accuracy.3D laser scanning modern technology is changing top quality control in manufacturing. 3D laser scanning modern technology has actually evolved considerably in recent years, its essential Visit This Link concept remains uncomplicated: catching the accurate geometry of items using laser beam of lights. Integrating 3D laser scanning right into high quality control processes enhances the precision and efficiency of evaluations throughout manufacturing (3D Scanning). 3D laser scanning technology uses automated data capture, decreasing labor expenses and lessening human error. The cost of executing 3D laser scanning modern technology varies considerably, generally varying from $10,000 to $100,000, depending on software, tools, and training

Report this wiki page